- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- News

- Answers

- Contact

- About

News

- 0

- 0

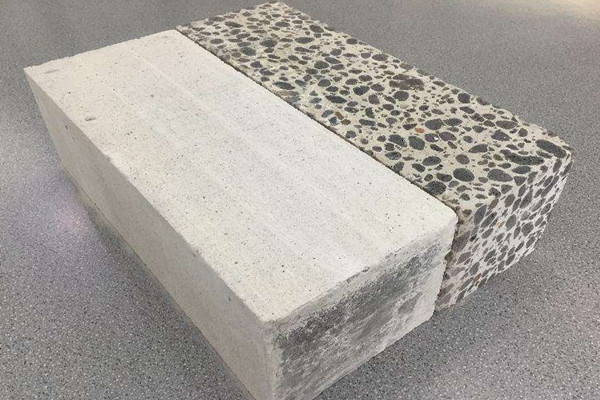

The solution to the collapse of foam concrete

If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Guotai Junan released a research report saying that under the background of carbon neutrality, the scarcity of coal mines is prominent, and the value of assets will continue to increase. The high point of capital expenditure in the coal industry appeared in 2012. Under the general direction of carbon neutrality, the overall investment in the industry has slowed down, and capital expenditure has gradually declined. From 2021 to now, the Energy Bureau of the National Development and Reform Commission has only newly approved 17.4 million tons of foam concrete.

The common problems of foamed concrete are bubbling, cracking, collapse, shrinkage, and other phenomena. To treat these phenomena, the proper medicine can be found, and the cause can be effectively solved.

The main reason for the collapse of foamed cement is that the cement solidification speed is too slow. We can solve this situation from the following aspects

1. Add accelerator to improve the setting time of foamed cement

Accelerators are used in more and more concrete applications. Foamed cement has high requirements for accelerators. It is not just a fast setting but also needs to be adapted to the performance of foamed cement, and accelerators cannot be added. After affecting the foaming situation.

2 Add an early strength agent to improve the early strength of foamed cement and reduce the stress generated during the exothermic process of cement hydration. Only when these two forces are balanced can it be ensured that the foamed cement will not crack and collapse in the later stage.

3. An appropriate amount of sulfoaluminate cement can be added, which many manufacturers choose to use in winter, and the cost performance is still relatively high. However, this amount of addition should also be paid attention to. It should not be added blindly. After many customers add sulfoaluminate cement, the finished product becomes very brittle in the later stage, without toughness, low strength, and severe pulverization. So we still have to adjust according to the current situation.

4 The water-cement ratio is not suitable. Collapse, retraction, bleeding, insufficient strength. To a large extent, it has something to do with the inappropriate water-cement balance. The adjustment of the water-cement ratio is a technical activity that requires trial and error. It has a lot to do with the cement of foamed cement and the fly ash aggregate, and it needs to be practiced repeatedly according to the actual situation. In this, we can add a plasticizer to adjust the water-cement ratio. This effect is very immediate.

The above contents are some solutions summed up by Tongrun according to the reasons for the collapse of foamed cement. If you encounter other problems or reasonable solutions in the actual process, you are also welcome to communicate us.

China's non-manufacturing purchasing managers index for March was released by the China Federation of Logistics and Purchasing and the Service Industry Survey Center of the National Bureau of Statistics today. An index of business activity for the non-manufacturing sector as a whole fell below 50 percent.

China's non-manufacturing business activity index was 48.4%, down 3.2 percentage points from the previous month. The new orders index was 45.7 percent, down 1.9 percentage points from the previous month, indicating a significant slowdown in the growth of supply and demand in the non-manufacturing sector from the previous month. In terms of sectors, the business activity index and new order index of transportation, accommodation and catering, culture, sports and entertainment, and tourism-related industries all declined significantly from the previous month.

Then the foam concrete of the market may be affected by significant changes, the price will also be volatile, if you want to know the latest news of the foam concrete, welcome to contact us.

Inquiry us

PREVIOUS NEWS

High Purity Nano Diamond Powder CAS 7782-40-3, 99%

NEXT NEWS