Silicon Carbide SiC CAS 409-21-2

About Silicon Carbide SiC Powder:

Silicon carbide (SiC) is a lightweight ceramic material with high strength properties comparable to diamond. Silicon carbide is an excellent ceramic material for applications requiring good erosion, high-temperature resistance and abrasive resistance. Our company also can supply silicon carbide ceramic products.

If you want to know silicon carbide price, please send inquiry to sales1@rboschco.com

Silicon carbide is also commonly called silicon carbide semiconductor, which is a type of semiconductor. Silicon carbide is very hard and is a synthetic crystal of silicon and carbon. Silicon carbide has two kinds green silicon carbide and black silicon carbide Its chemical formula is SiC. Since the end of the 19th century, sic silicon carbide has been an important material for sandpaper, grinding wheels and cutting tools.

The microscopic shape of silicon carbide powder is hexagonal crystals, the Mohs hardness of silicon carbide is 9.2, the Vickers microhardness is 3000-3300 kg/mm2, the Knoop hardness is 2670-2815 kg/mm, and the microhardness is 3300 mm per cubic millimeter. It is higher than corundum in abrasives and second only to diamond, cubic boron nitride and boron carbide. The density is generally considered to be 3.20 g/cm3, the natural bulk density of the silicon carbide abrasive is between 1.2-1.6 g/mm3, and the specific gravity is 3.20~3.25. Green silicon carbide uses petroleum coke and high-quality silica as its main raw materials, and salt is added as an additive. Its hardness is between corundum and diamond at high temperature through a resistance furnace, and its mechanical strength is higher than that of corundum.

Silicon carbide is a non-oxide ceramic that can be used in many products that must function in thermal (high thermal and thermal shock) and mechanically demanding applications. On the contrary, single-crystal SiC has the best performance, but the manufacturing cost is high.

Silicon carbide is composed of a tetrahedron of carbon and silicon atoms and has strong bonds in the crystal lattice. This produces a very hard material. Silicon carbide is not corroded by any acid, alkali or molten salt up to 800°C. Feel free to send an inquiry to get the latest price if you would like to buy Silicon Carbide SiC Powder in bulk.

How is Silicon Carbide SiC Powder produced?

The easiest way to make silicon carbide is to mix silica sand and carbon in an Acheson graphite resistance furnace at high temperatures between 1600°C (2,910°F) and 2,500°C (4,530°F).

Commercially, silicon carbide is produced by reacting a mixture of sand (silica) and coke (carbon) in a resistance furnace.

The self-conducting mixture is heated by direct current to temperatures up to 2700°C. A few days later, a product of iridescent black or green crystal aggregates was obtained, which was then crushed and graded. Crude grade (>10μm) silicon carbide powder cannot be sintered to a high density. For refractory applications, for example, use silicon nitride or silicon oxynitride, aluminosilicate glass, or a binder phase of self-bonding carbon and silicon to bond compacted coarse silicon carbide sand of the desired shape. For electric heating element materials, when the degree of direct bonding can be obtained, the high-purity gradient silicon carbide sand is sintered at a temperature of about 2400°C. The production of high density (low porosity) materials requires special conditions.

By decomposing the gaseous or volatile compounds of silicon and carbon in an inert atmosphere, silicon carbide can also be produced on a small scale, so that the reaction product deposits the carbide on a suitable thermal substrate.

Finally, since carbon has significant solubility in liquid silicon, it can be obtained by crystallization from carbon-rich molten silicon that is supersaturated with respect to SiC at high temperatures (~1650°C).

The final reaction formed the basis of mature self-bonding or reaction bonding technology combined with fine-grained silicon carbide powder.

Technical Parameter of Silicon Carbide Nanoparticles Nano SiC Powder:

| Product Name | MF | Purity | Particle Size | Crystal Form | SSA | Color |

| Silicon Carbide Nanoparticles | SiC | 99% | 60nm, 500nm | Cubic | 29m2/g | Gray green |

Applications of Silicon Carbide SiC Powder:

As a functional material in various optical and semiconductor devices, silicon carbide has attracted great interest from people. Due to its high stiffness, high conductivity and low coefficient of thermal expansion, it is considered an ideal material for large optical mirror applications and radiation detectors.

In addition, it is also used as a barrier material for high-temperature electronic equipment and parts that are highly susceptible to mechanical wear (such as bearing parts and seals). In addition, silicon carbide (SiC) is used in the first wall and cover assembly of the fusion reactor. Use candidate materials and use them in the coating of nuclear fuel particles for high-temperature gas-cooled reactors. In addition, silicon carbide has many other uses.

Grinding and cutting tools SiC cutting disc

Due to the durability and low cost of silicon carbide material, it is a popular abrasive in modern gems. In manufacturing, it is used due to its hardness during grinding, honing, water jet cutting and sandblasting.

Structural materials

Silicon carbide is used as a support and shelf material in high-temperature furnaces, for example for firing ceramics, glass fusion or glass casting. SiC kiln racks are much lighter and more durable than traditional alumina racks.

Car parts

Carbon ceramic (silicon carbide) disc brakes of the Porsche Carrera GT.

Siliconized carbon-carbon composites can be used for high-performance "ceramic" brake discs because they can withstand extreme temperatures. These brake discs are used in some road sports cars, super sports cars and other high-performance cars, including Porsche Carrera GT, Bugatti Veyron, Chevrolet Corvette ZR1, McLaren P1, Bentley, Ferrari, Lamborghini and some specific high-performance Audi cars. Silicon carbide is also used in diesel particulate filters in sintered form. It is also used as an oil additive to reduce friction, emissions and harmonics.

Casting crucible

SiC is used in crucibles to hold the molten metal in small and large casting applications.

Electronic circuit components

Silicon carbide is the first commercially important semiconductor material. Henry Harrison (Henry Harrison Chase Dunwoody) applied for a patent for a crystal radio "silicon carbide" (synthetic silicon carbide) detector diode in 1906. This technology has been widely used in shipboard receivers.

Astronomy

Low coefficient of thermal expansion, high hardness, rigidity and thermal conductivity make silicon carbide an ideal mirror material for astronomical telescopes.

Filament pyrometer

Test flame and glowing SiC fiber. The flame is about 7 cm (2.8 inches) high. Silicon carbide fibers are used in optical technology, called the filament high-temperature method, to measure gas temperature.

Graphene production

Silicon carbide can be used to produce graphene because its chemical properties can promote the epitaxial production of graphene on the surface of SiC nanostructures.

Steel production

Silicon carbide wafers for steelmaking. Silicon carbide is dissolved in an alkaline oxygen furnace used for steelmaking and used as fuel. The extra energy released allows the furnace to treat more waste with the same amount of molten iron. It can also be used to increase the tapping temperature and adjust the carbon and silicon content.

Jewelry

As a gemstone used in jewelry, silicon carbide is called "Synthetic Moissanite" or simply "Moissanite" after the mineral name.

Fishing rod guide

Silicon carbide is used to make fishing tackle because of its durability and wear resistance. The silicon carbide ring is installed in a guide frame, which is usually made of stainless steel or titanium to prevent the pipeline from contacting the bar stock. The lifting ring provides a low-friction surface, which can improve the casting distance, while providing sufficient hardness to prevent the braided fishing line from causing wear.

Packing & Shipping of Silicon Carbide Nanoparticles Nano SiC Powder:

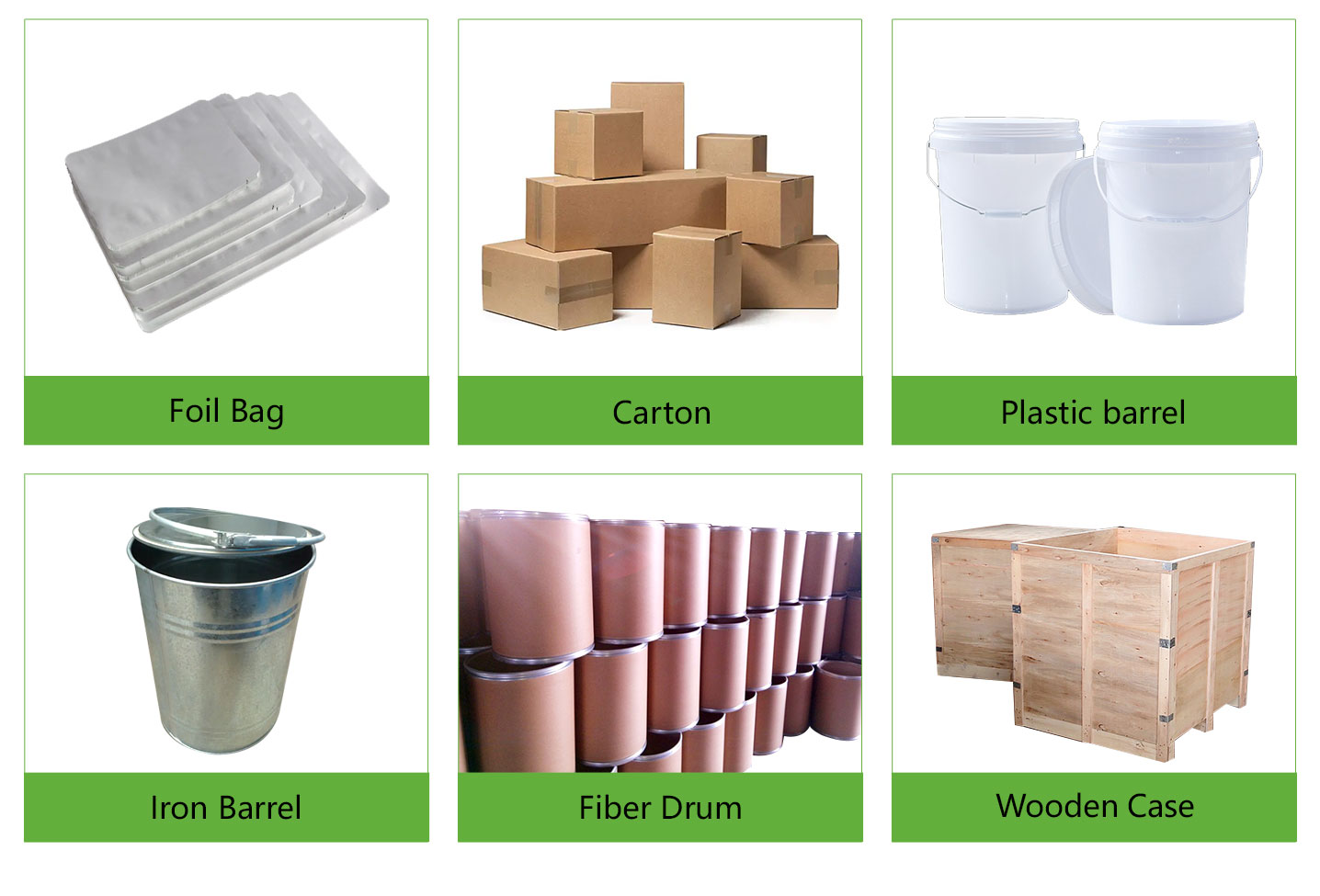

We have many different kinds of packing which depends on the silicon carbide nanoparticles quantity.

Silicon carbide nanoparticles packing: vacuum packing, 1kg/bag, 25kg/barrel, or as your request.

Silicon carbide nanoparticles shipping: could be shipped out by sea , by air, by express as soon as possible once payment receipt.

Silicon Carbide Properties | |

| Other Names | Carborundum, alpha sintered SiC, Hexoloy, methanidylidynesilicon, moissanite, SiC powder |

| CAS No. | 409-21-2 |

| Compound Formula | SiC |

| Molecular Weight | 40.1 |

| Appearance | Green to Black or Gray Powder |

| Melting Point | 2730 °C |

| Boiling Point | N/A |

| Density | 3.0-3.2 g/cm3 |

| Solubility in H2O | N/A |

| Electrical Resistivity | 1 to 4 10x Ω-m |

| Specific Heat | 670 to 1180 J/kg-K |

| Tensile Strength | 210 to 370 MPa (Ultimate) |

| Thermal Conductivity | 120 to 170 W/m-K |

| Thermal Expansion | 4.0 to 4.5 µm/m-K |

| Young's Modulus | 370 to 490 Gpa |

Silicon Carbide Health & Safety Information | |

| Signal Word | Warning |

| Hazard Statements | H315-H319-H335 |

| Hazard Codes | Xi |

| Risk Codes | 36/37/38 |

| Safety Statements | 26-36 |

| Transport Information | N/A |

Inquery us

PREVIOUS Products

Chromium Carbide Cr3C2 Powder CAS 12012-35-0

NEXT Products